For historical information only, do not use for navigation or aviation purposes!

| Coordinates | N522825 E0132406 (WGS84) Google Maps |

| Elevation | 164 ft |

| Location indicator | DDTF (195x), EDBB (196x-1995), EDDI (1995-2008) |

Germany during the Cold War Map

The history of the Cold War airfields: Berlin-Tempelhof Airport

Contents

Page 1: From the beginnings until 1945

Page 2: Tempelhof after World War II & Berlin Airlift ← you are here

Page 3: Tempelhof Airport: The 1950s

During the Cold War

Use

US military aerodrome and airport

At the end of the war in 1945

Situation

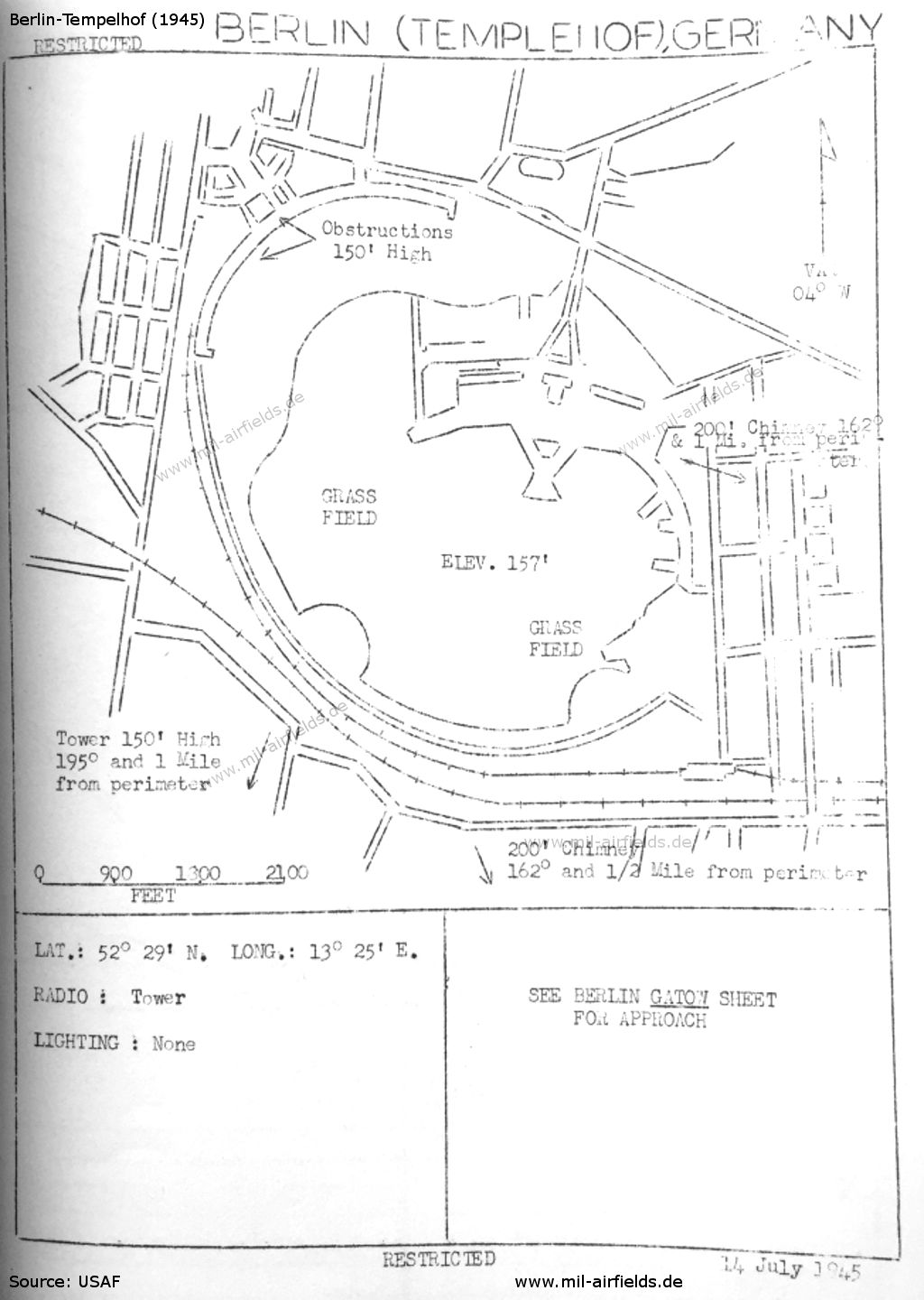

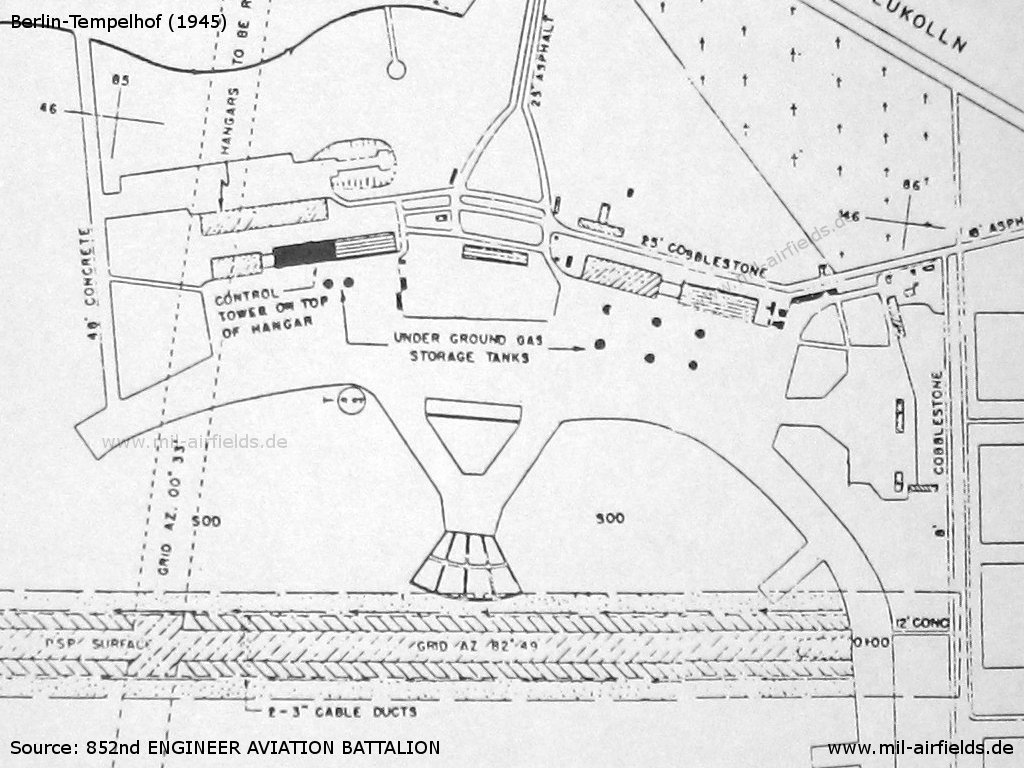

Tempelhof Airport on a US map at the end of the war in July 1945

Source: DoD

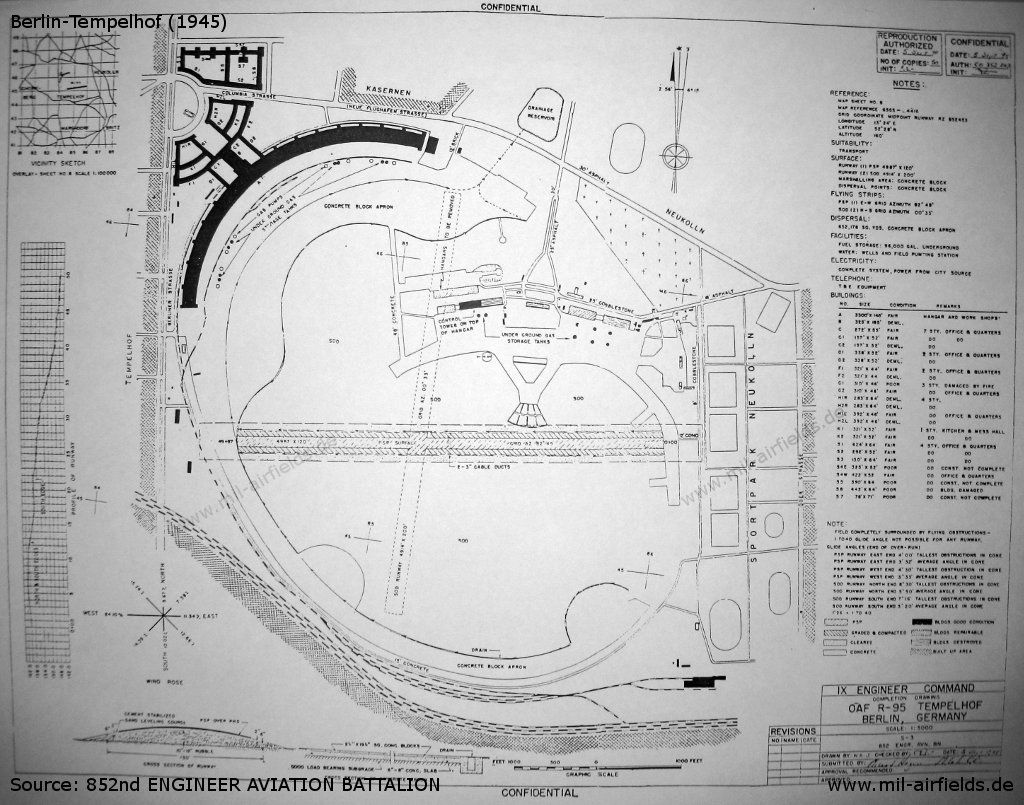

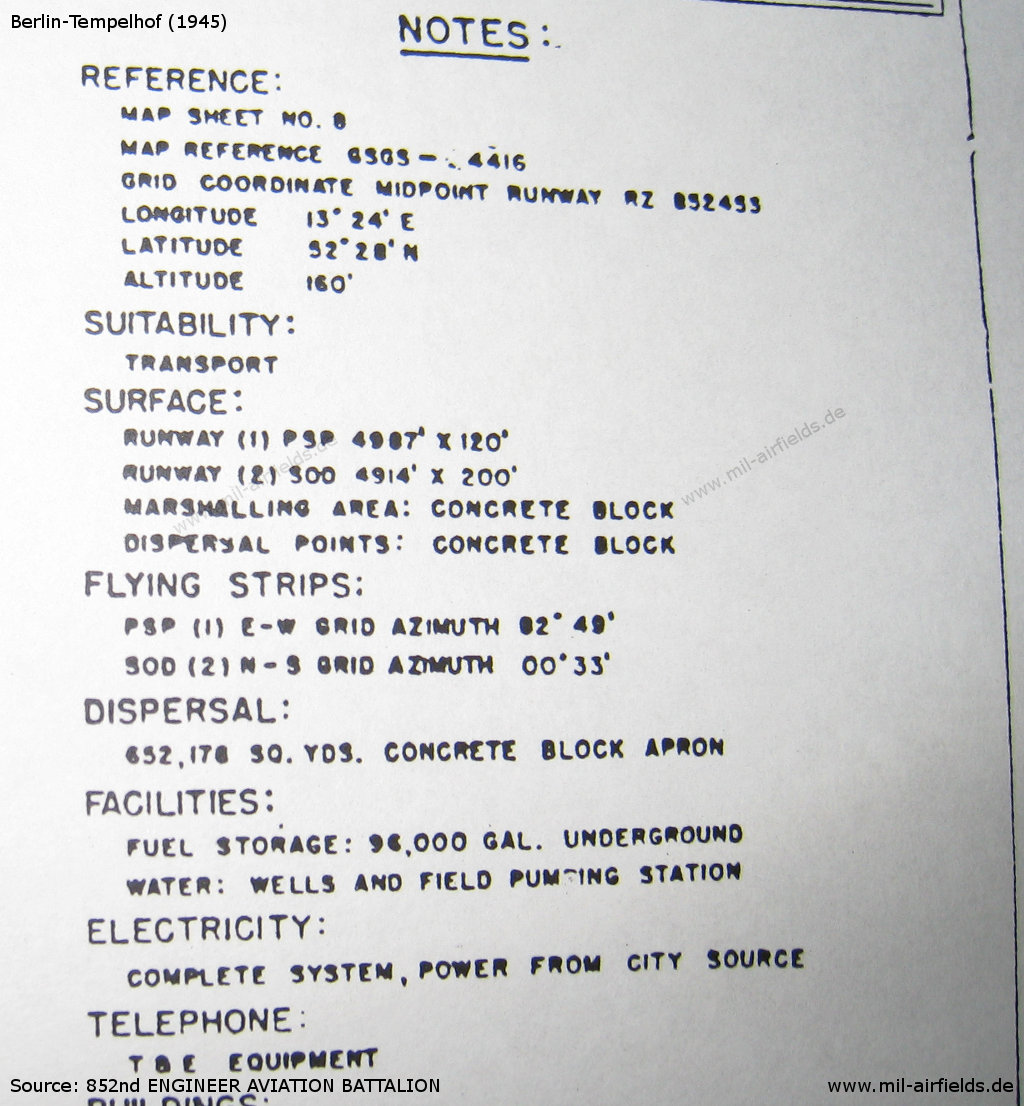

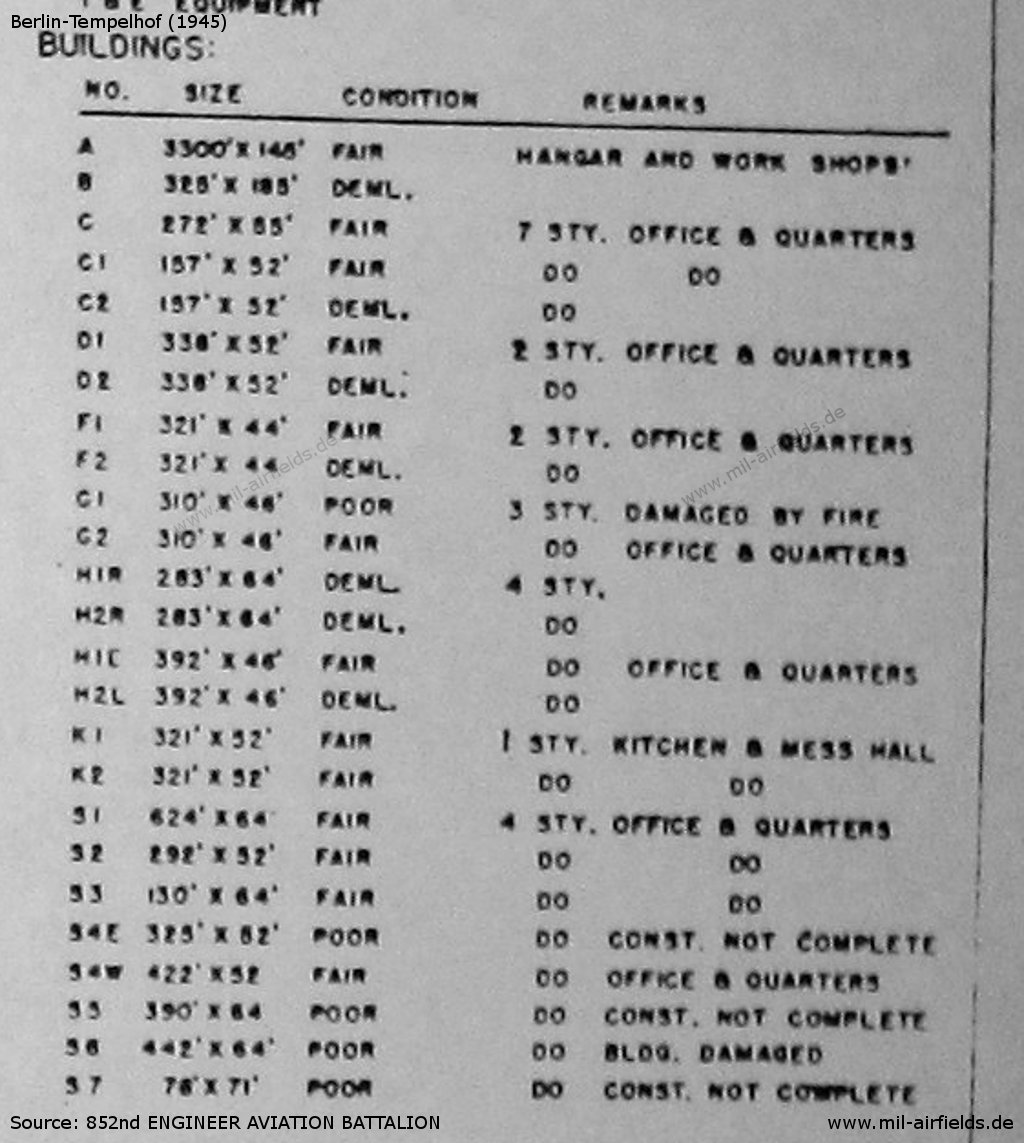

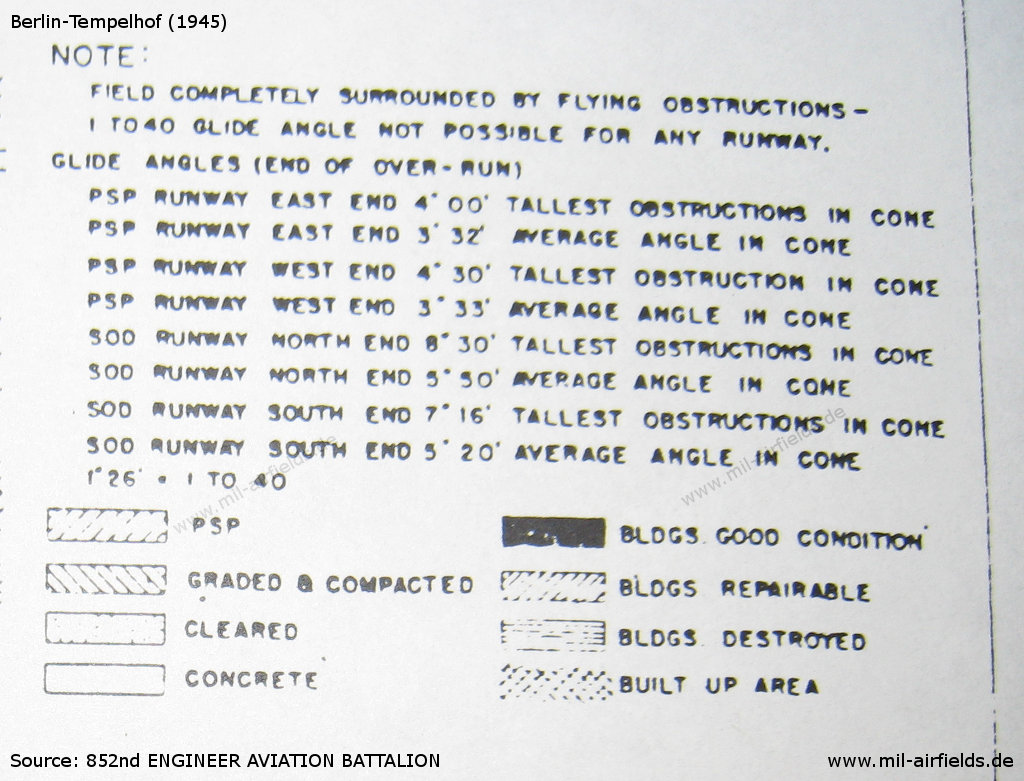

Tempelhof Aerodrome on a US map from September 1945

Source: 852nd ENGINEER AVIATION BATTALION, via U.S. Army Corps of Engineers / Office of History and Patrick Weidhaas

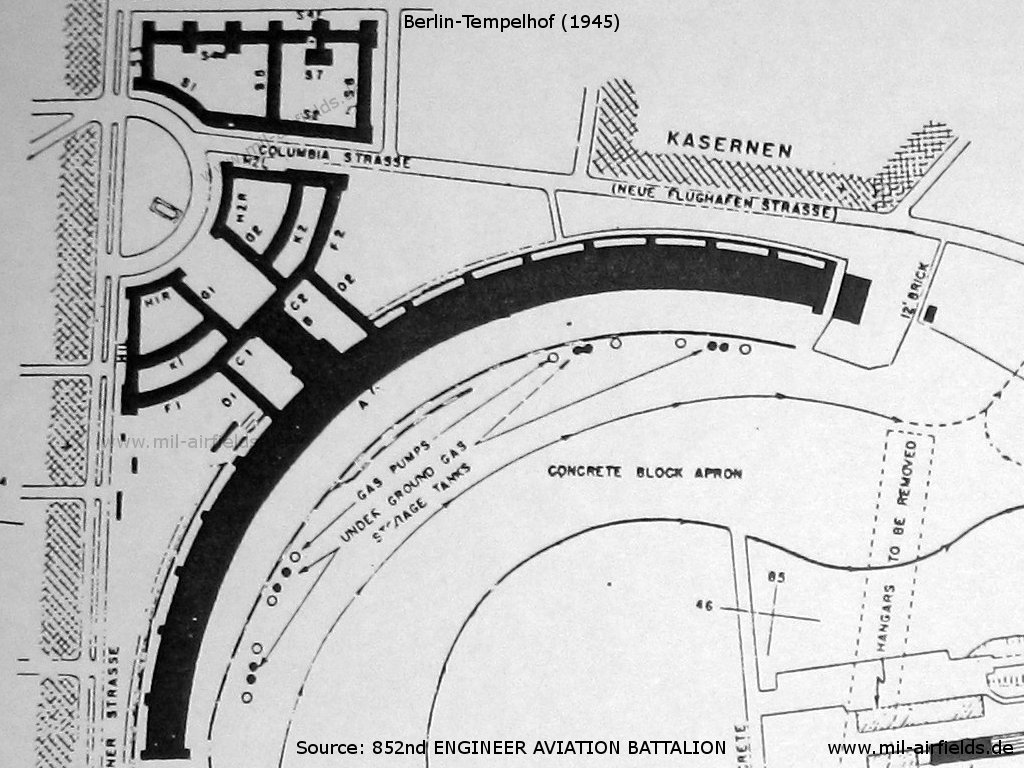

Enlargement: Main building

Enlargement: Old airport and new PSP runway

Enlargement: Data

Enlargement: List of buildings with condition

Enlargement: Obstructions in the approach sectors

Enlargement: Signature

Additional information

Reconstruction in 1945

The following is the final report on the reconstruction of the airfield by US troops in September 1945

PSH: Prefabricated Hessian Surfacing

PSP: Pierced steel planking

PSH: Prefabricated Hessian Surfacing

PSP: Pierced steel planking

HEADQUARTERS 852nd ENGINEER AVIATION BATTALION

A-H-2

APO 126, US. Army

10 September 1945

600.10

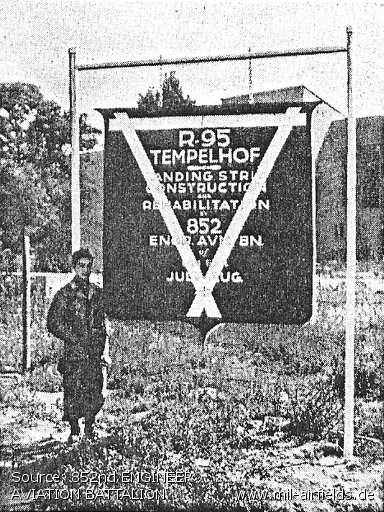

SUBJECT: Completion Report, OAF Field R-95, Tempelhof, Berlin, Germany.

TO:

Commanding Officer

IX Engr. Comd. (Main)

APO 126, US. Army

A-H-2

APO 126, US. Army

10 September 1945

600.10

SUBJECT: Completion Report, OAF Field R-95, Tempelhof, Berlin, Germany.

TO:

Commanding Officer

IX Engr. Comd. (Main)

APO 126, US. Army

In compliance with Memorandum 15-7, Hq., IX Engineer Command, dated 26 March 1945, the following completion report for OAF Field R-95, Tempelhof, Berlin, Germany, is submitted:

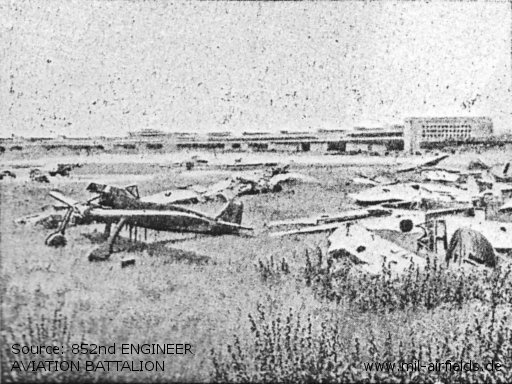

1. History of the Project: The Airdrome itself has an extensive and interesting history. Early in 1919 work was put in hand to transform the old military field at Tempelhof into a commercial airfield, and by 1925 it had become one of the best equipped and most famous in Europe. It is situated in the southern suburbs of Berlin, between Schöneberg and Neukölln, some 2 ½ miles due south of the famous Unter den Linden street, center of the city. This unique site added to its importance and in 1936 a great program of extension and rebuilding was planned. Hitler is said to have had a hand in much of the planning and design and directed Goering and Dr. Ernst Savebiel, Architect of the Reich Air Ministry, to spare no expense in making it one of the finest and largest in Europe. Construction proceeded from 1936 to 1939 according to the new plans and included the huge arc-shaped hangar, a 3800 foot segment of a circle of approximately a mile in diameter, and the large four to seven story administration buildings directly behind the hangar. From 1939 to 1941 the construction was directed mainly to repairs and finishing up the work on the main buildings. The new hangars and buildings were never utilized for their intended civilian air transport use and considerable construction remained in 1941 when all work was stopped. These hangars and buildings were used thru the war period for the production of war materials. One concern, "Telefunken", manufactured aircraft detection devices from 1940 to 1943. The concern, "Weser", operated here from 1939 to the end of the war assembling JU 87's and Focke-Wulf 191's. Lufthansa, the commercial airline, operated for the entire war period for military personnel and high priority civilian travel from the old Airdrome facilities site on the east side of the field. Lufthansa also had a repair set up for JU 87's and Focke- Wulf 200s in the old hangar site. No extensive operations were performed from this field by the GAF other than the necessary test hops for the planes being assembled by "Weser" and small scale night flying operations. The field was heavily defended by numerous flak installations and was subjected to only two bombing raids, Jan. ‘44 and March '45. During the fall of Berlin the buildings and installations were hit by shell fire and while no actual defense was made by the Germans of the field nor did any fighting occur on the field, the flak installations used also for ground defense of Berlin by the Germans drew considerable Russian artillery fire. After Berlin fell 23-24 April 1945, considerable fire damage occurred in most all of the structures and all glass in every building was broken. On the sod flying field and concrete block aprons the damage was slight in comparison and what few crater and shell holes remained after Berlin fell had already been filled by Russian forces when our forces took over.

On 1 July at 1000 hours this organization received word from the 924th Regimental Headquarters to proceed to Halle, Germany, the collecting point for the American Occupational Forces that were to march to Berlin to occupy the American Sector of the Berlin District. The advance party consisting of Company "B" with attached personnel of H & S left Fritzlar (Y-86) Germany, the previous construction assignment, for Halle 0700 hours 2 July arriving at 1500 hours. On 4 July at 1600 hours an advance patrol of Lt. Brown, Asst. S-3. and two NCO's with a 1/4 ton 4X4 truck left Halle by plane, C-47, for the Tempelhof Airfield to secure billets for the advance party enroute and to familiarize themselves with the installation in preparation for surveys and construction. The main body of Company “B”, the advance unit, left Halle 0930 hours, 5 July, in convoy with occupational units and arrived at the Tempelhof Airdrome 1800 hours. Company "A" proceeded to Tempelhof 9 July, Company and H & S July 11. By 11 July the entire battalion except some heavy equipment was located in Berlin.

Surveys for the preliminary layout were completed 7 July and the layout and engineering survey was presented to Regimental Hqs., 8 July, for approval. Construction and rehabilitation was started 0700 hours, 10 July.

The initial work undertaken was the construction of the runway, repairs to the roof of the main hangar, crater and shell hole surface repairs on the concrete block aprons, and debris removal.

In connection with the runway project the base course of rubble fill was completed over the entire flight strip by 28 July, and a final course of rubble to fill in the low spots and bring up to grade was completed 8 August. The sand leveling course fill was started 20 July and completed 1 August. The stabilization of the sand course with cement was started 29 July and completed 14 August. The laying of the PSP on the runway commenced 18 August and was completed 1700 hours 28 August, all companies participating.

Crater and shell hole surface repairs on the parking and connecting aprons began the first day of work on the job and continued thru the entire period of the units stay on this airdrome. This project was handled by Company „A“.

The repairs and reroofing of the main hangar roof began 12 July and continued thru the life of the job. This work was done by Company „C“.

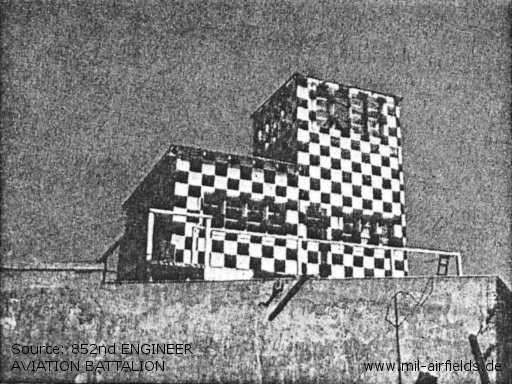

Company „C“ also erected a control tower according to OAF specifications atop a hangar in the old facilities site of the airdrome in the period from 24 July thru 25 August.

Company "B" was assigned repairs and office partitioning work for Base Operations in the Disembarkation Hall of the main hangar building 15 August. This work was taken over by Company „C“ 25 August, and was in progress toward completion when the unit left Berlin.

During the period 10 August to 22 August Company "A", in addition to assigned projects, completed a pipe rail fence in front of Headquarters at Gate 1 and leveled off chimneys and high walls of bombed structures in the glide cone off the west end of the runway.

Company „C“ in addition to its assigned projects mentioned previously completed during the period 13 August to 10 September a pistol and carbine range for Base personnel in the park north of Columbia Strasse adjacent to the airdrome.

On 23 August this organization received orders via radio to complete Fritzlar, Y-86, as per original recommendations for an OAF Fighter Bomber Base and Company "B" with attached personnel of H & S was taken off of construction at Tempelhof and moved to Fritzlar, Y-86, 0700 hours, 25 August. Company ”B" assignments on Tempelhof were assumed by "A" and "C" Companies.

A small section of concrete block taxiway connecting the new main apron with the old apron area, some 600’ in length, was resurfaced with concrete by "A" Company in the period 1 September thru 10 September. In this same period a start was made on the wrecking of the old hangars and clearing of the right of way for the sod runway strip.

Construction according to OAF standards was completed 10 September, the date previously set as the completion date. There was a little work remaining on several projects, (operations office block, hangar roof repairs and right of way clearance), but beyond that date the work could more appropriately be classed as maintenance than construction and civilian labor could with a little supervision complete all assignments.

2. Construction Data: Construction on this field was covered by work order No. 177 dated 8 August and was received by this organization 13 August. This order directed that transport facilities be rehabilitated or constructed in accordance with OAF standards. There was more than ample space intact to provide for the necessary housing facilities. Beyond the construction of the runway, control tower, repairs to the hangar roof and parking apron and taxiways and debris cleanup, the work performed by this organization in cooperation with Air Corps personnel, who were also engaged in rehabilitation consisted of numerous projects requested by the Base Commander that would enable this field to operate in keeping with its position of an Occupational Headquarters Airfield.

The selection of a suitable alignment for the runway proved to be a difficult problem as the entire field is surrounded by tall structures, most of which are little damaged. The one to forty glide angle specification was virtually impossible in any direction so it was decided to site the runway in the direction of the most prevailing winds, East-West, and approval for this was secured thru higher headquarters The average glide angle at each end of this runway is approximately 1 to 16. A sod runway at approximately a right angle to the PSP East-West runway has been selected and marked for use in case of extreme cross winds and the glide angle at each end of this strip is approximately 1 to 10.

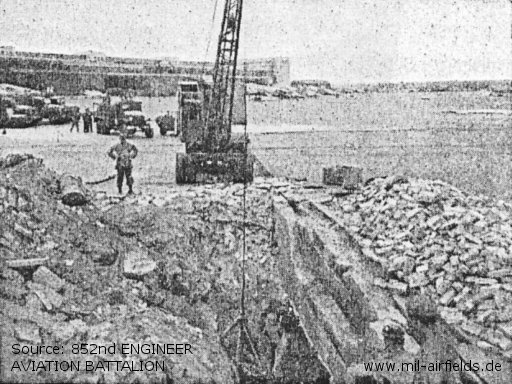

In construction of the base for the PSP runway the chief problem was one of materials. Berlin is situated in an area practically void of any gravel banks or stone quarries. All materials of this nature used in Berlin had to be trucked or brought in by rail at a minimum distance of 30 kilometers. Numerous stock piles of gravel and crushed stone were found on unfinished projects in the vicinity of the field but it was thought best to reserve these for concrete aggregates that would be needed for other projects on the field. Inasmuch as most rail lines into Berlin had not yet been repaired at the beginning of the job and as clearance thru the Russians for gravel or crushed stone would present a delaying problem it was thought best to consider materials in sufficient quantities in the close vicinity of the airdome. A most casual observation revealed that the most abundant material in Berlin was and is rubble, so it was decided to utilize this in the initial base course fill. A minimum thickness of six inches of rubble was used and in the course of placing this material it was watered and rolled to as close to grade as possible.

The unevenness of this rubble base was too rough to place PHS and PSP directly upon it so an approximate 2" layer of sand was placed over it as a leveling course. Sand was obtained off the southern boundaries of the flying field and this sand was mixed with a sufficient clay that was found over the sand to act as a binder. Upon the application of this sand leveling course it was thought best to stabilize it as a protection against all weather. Cement was used and while no plant was in operation in the Berlin District a sufficient quantity was obtained by collecting together the many bag piles of cement on unfinished construction in the Tempelhof District. This cement was found in all stages of deterioration and a safe margin over and above the estimated amount was used to insure an ultimate stable condition. The first runs were made with 8-10% by volume of cement and this was later raised to 12-15%.

Five hundred foot sections of the 120' base was stabilized each day. Cement was bag spotted on the grade according to percentage needed, and spread by hand. Mixing in place was accomplished by patrol grader and an improvised spring toothed harrow. Water to the proper optimum moisture content was applied by three fire hoses out of 1500 gallon trailer tanks with a German fire pump. Compaction was secured with rubber-tired wobbly wheel and 5-8 ton tandem rollers. Curing was accomplished with a .2 to .3 gallon per square yard bituminous cover. The over all results were very satisfactory and provided a good even firm and stable support for the PHS and PSP. The laying of the PHS and PSP did not present any problem and was accomplished according to standard practice.

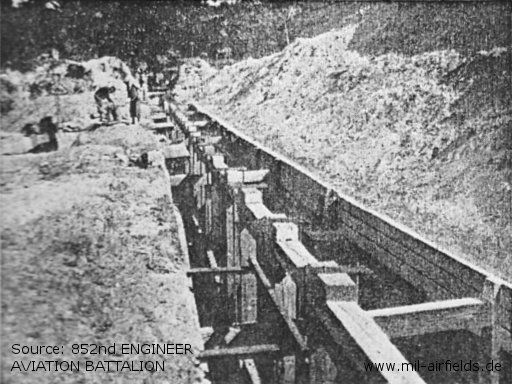

Considerable work was involved in the repairs to the elaborate drainage system of the field but no particular construction problem was encountered. These repairs were chiefly due to breaks in lines at bomb craters and necessitated replacing new pipe and concrete and masonry work together with sizeable excavations. The PSP runway strip itself has a general fall from east to west and the excessive runoff can be taken care of from there in the drainage system on the concrete block aprons.

The huge parking aprons in front of the hangar and adjoining the two ends of the PSP runway are constructed of concrete blocks, half a meter square (19 ¾ inches square) on top of a 6—8 inch low grade concrete fill slab. Some 75 crater holes of approximately 6500 sq yds in area on these aprons had been previously back filled by both the Germans and the Russians but were not able to support plane loads and had to be resurfaced. Initially, resurfacing was done according to the original construction method but later the full surface thickness was repaired with a concrete slab to speed up the work.

A control tower according to OAF specifications was erected atop of one of the few remaining hangars in repairable condition in the old airdrome facilities site. The site selected is almost mid point of the field and from a height of approximately forty feet affords an excellent view of the strip together with parking and taxiing aprons. This hangar selected for the control tower has sufficient space for housing of the fire fighter crew and equipment as well as the engineering office for maintenance of the field.

The roof of the main arc-shaped hangar contained numerous bomb, shell and flak holes and these many visible roof fractures were at first repaired individually with sheet metal decking, insulation and tarred roof patches. Due to the many invisible breaks in this roof this means of repair did not solve the leak problem satisfactorily and a full reroof covering was made using rolls of Hessian Matting.

While debris clean up did not present any constructional aspect it did represent a job of project size as almost all of the hangar area had been devoted to a plane assembly plant and was full of heavy equipment and parts. The aprons in front of the hangar were also almost completely taken up by huge debris piles as well as parts storage areas. Crane work with heavy equipment trailers had to be used to clear these areas.

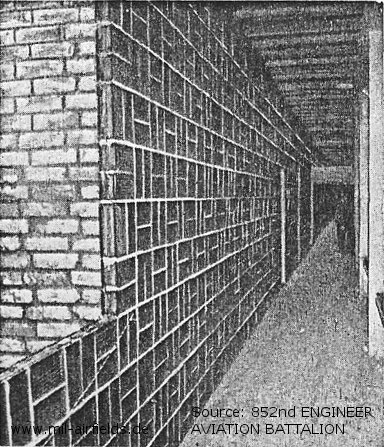

The remaining work accomplished at this installation, while not representing constructional problems, did reflect the extent and variety of work that can be demanded of and accomplished by Aviation Engineer troops. Demolition work was performed in removing flying obstructions consisting of chimneys and high walls of bombed structures in the glide angle off the west end of the PSP strip. A pipe rail fence and gates were constructed in front of the court at the main entrance and Headquarters building. A repair and renovation project utilizing glass brick along with the usual burnt clay brick and tile for partitions was constructed for the Base Operations Office block in the Disembarkation hall. This work also involved steel sash repairs, marble wall facing repairs and extensive reglazing.

Still another project was an old small German firing range which was converted into a carbine and pistol range for base personnel in a park adjacent to the airdrome.

Existing underground gas storage of eight 12,000 gallon tanks in front of the main hangars was found in useable condition and the original firm employed in the installation of the system when the field was first reconstructed was used to clean out this system and place it in working order.

The soil according to the Casagrande classification is a silty sand, SF, and though not the best type for self drainage, evidence seems to indicate that no particular drainage difficulty was encountered during wet seasons. During a protracted wet spell this soil is liable to lose a considerable amount of its bearing capacity and a paved surface will be necessary to support heavy plane loads. The water table is at a considerable depth, some 12 feet during the summer, and little if any frost action is anticipated.

3. SUMMARY OF MAN HOURS EXPENDED:

| Item | Man Hours Troop Labor | Man Hours Civilian Labor | Total |

|---|---|---|---|

| Runway | |||

| Clearing right of way | 160 | ||

| Preparing subgrade | 175 | ||

| Placing rubble fill | 422 | ||

| Placing sand leveling course | 222 | ||

| Hauling rubble and sand | 10,445 | ||

| Traffic control on rubble fill | 2,547 | ||

| Stabilization of sand leveling course | 2,782 | 5,000 | |

| Laying PHS | 568 | 896 | |

| Laying PSP | 3,237 | 134 | |

| Hauling construction material | 4,905 | 348 | |

| Debris removal from hangars, aprons and taxiways | 6,521 | ||

| Repairing and reroofing hangar roof | 12,000 | 1,200 | |

| Repairing crater holes on apron | 10,100 | 10,600 | |

| Repairing drains on field | 3,171 | 2,906 | |

| Construction of control tower | 1,272 | ||

| Erection of barbed wire fence and gate at main entrance to field | 1,000 | ||

| Construction of carbine and pistol range | 2,050 | 1,800 | |

| Wrecking buildings in the west end glide angle of PSP runway | 784 | ||

| Rehabilitating masonry partitions for operations office | 3,000 | 3,200 | |

| Construction of airfield markings | 620 | 160 | |

| Construction of Engineer Construction Office | 50 | 650 | |

| Surveying and drafting | 1,602 | ||

| Clearing buildings for traverse sod runway | 1,300 | 1,800 | |

| Concreteing taxiway | 1,800 | 1,300 | |

| Miscellaneous | |||

| Grand Totals | 72,333 | 30,048 | 102,381 |

4. EQUIPMENT HOURS:

| Machine | Hours |

|---|---|

| Tractor, D-7 | 1.700 |

| Tractor, D-4 | 180 |

| Tractor, Case | 740 |

| Shovel | 700 |

| Shovel, Truck mounted | 279 |

| Motor grader, road | 720 |

| Roller, 5/8 | 357 |

| Roller, rubber-tired | 259 |

| Grader, Towed | 125 |

| Tank, water, trl-mtd | 275 |

| Distributor, bitumen | 289 |

| Mixer, concrete, 14 S | 332 |

| Scraper, carryall | 231 |

| Trucks, 2 1/2 TD | 12,018 |

| Trucks, 4 TD | 1,804 |

| Total | 19,372 |

5. MATERIALS USED:

| Item | Amount |

|---|---|

| Runway | |

| - Rubble for fill | 13,000 cu yds |

| - Sand for leveling course | 6,500 cu yds |

| - Cement for stabilization | 868 tons |

| - PHS | 1,450 rolls |

| - PSP | 1,600 bdle |

| - Pickets | 1,100 ea |

| - Tar, curing | 13,000 gals |

| Cement for concrete repairs | 430 tons |

| Sand for concrete repairs | 700 cu yds |

| Gravel for concrete repairs | 1,350 cu yds |

| Concrete blocks | 8,069 ea |

| Barbed wire | 246 rolls |

| Glass bricks (9 ¾'' x 5''><3 1/4") | 7,559 ea |

| Roofing tar | 46 tons |

| Roofing paper | 230 rolls |

| Lumber | 2,936 bd ft |

| Paint | |

| - White | 100 gals |

| - Black | 25 gals |

| - Red | 5 gals |

| - Yellow | 5 gals |

6. POL:

| Item | Amount |

|---|---|

| Gasoline | 26.572 gals |

| Oil | 2,250 gals |

| Diesel oil | 5,225 gals |

| Grease | 734 lbs |

Loading rubble for runway base from ruins of Berlin

Grading initial rubble course runway base

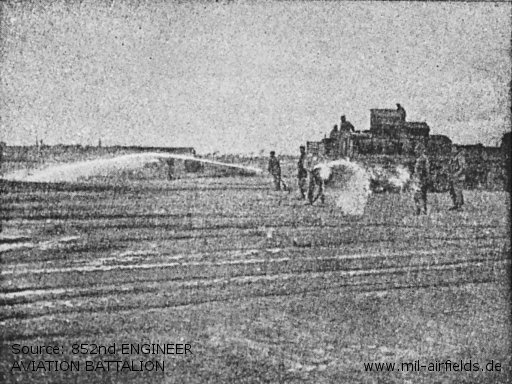

Wetting down rubble base during rolling

Spreading sand-clay leveling course over rubble base

Loading sand-clay leveling course

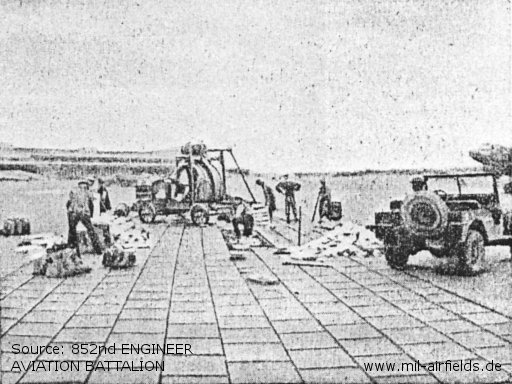

Spreading cement for stabilization of sand-clay leveling course

Mixing of sand-clay stabilization accomplished with spring toothed harrow

Further mixing with grader sand-clay cement stabilized course

Application of water to sand-clay cement mix to optimum content

Rolling of sand-clay cement mix.

Application of bitumen for cure of stabilized course

Laying PSP over PHS on stabilized course with rubble base

First plane off of completed runway 1700 hrs. 28 August 1945 plank laying crews of C. and A. companies given trip on initial takeoff

Concrete block apron repairs

Debris removal on field of project proportion

Repairs to main surface runoff drain in bomb crater

Main hangar roof repair

Pipe rail fence and flag. Headquaters Gate 1

Operations block partitions & renovation showing glass brick for light in inside rooms

Resurfacing concrete block taxiway with 4'' - 5'' concrete

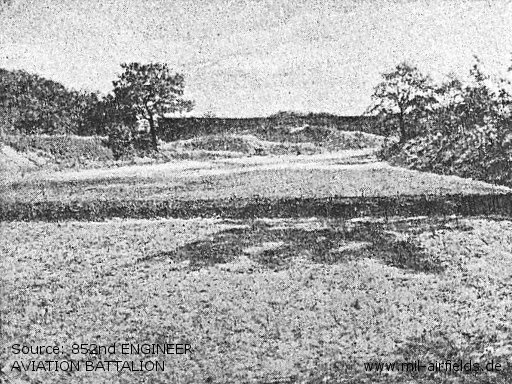

Construction of target butts pistol and carbine range

General view from target butts pistol and carbine range

Aerial view of field marker. Also shows area of control tower - top of photo

Aerial view of arc shaped Hangar structure

Aerial view looking South South-West of field showning completed PSP runway, - bulge in runway is PSP crossover for sod strip for use in extreme crosswinds

Aerial view looking north of field

Completed control tower, OAF specifications

Job sign at Gate 4 (vehicular traffic to field)

In the 1940s and Berlin Airlift

Situation

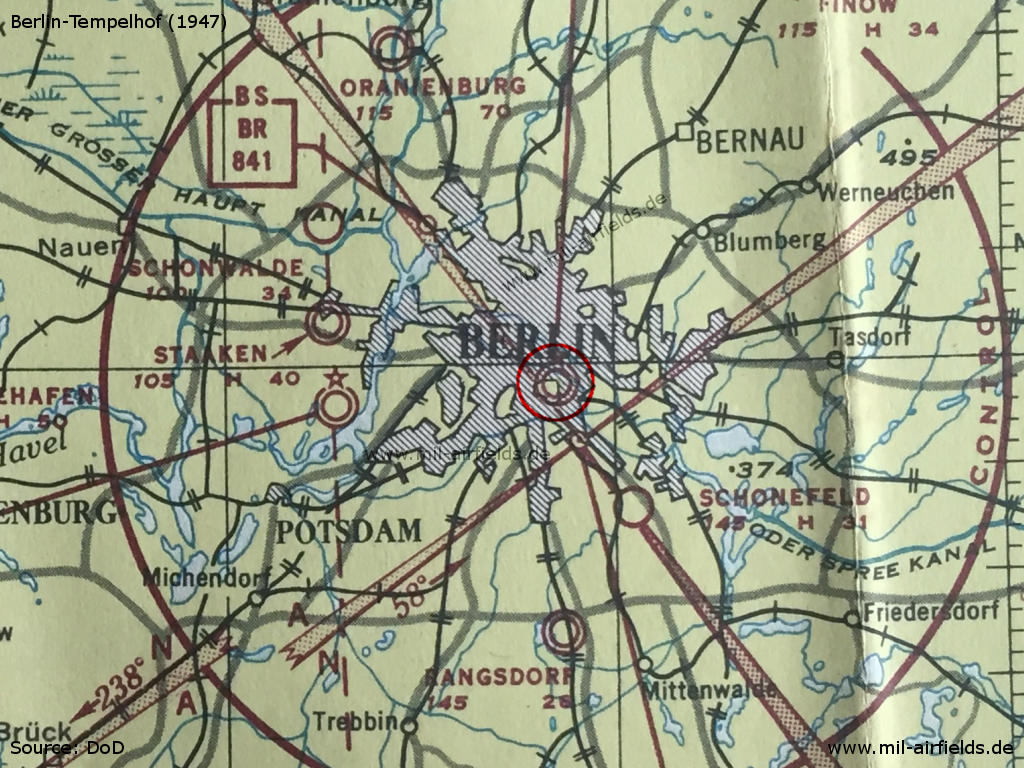

Tempelhof Airfield on a map from 1947

Source: US DoD

Overview

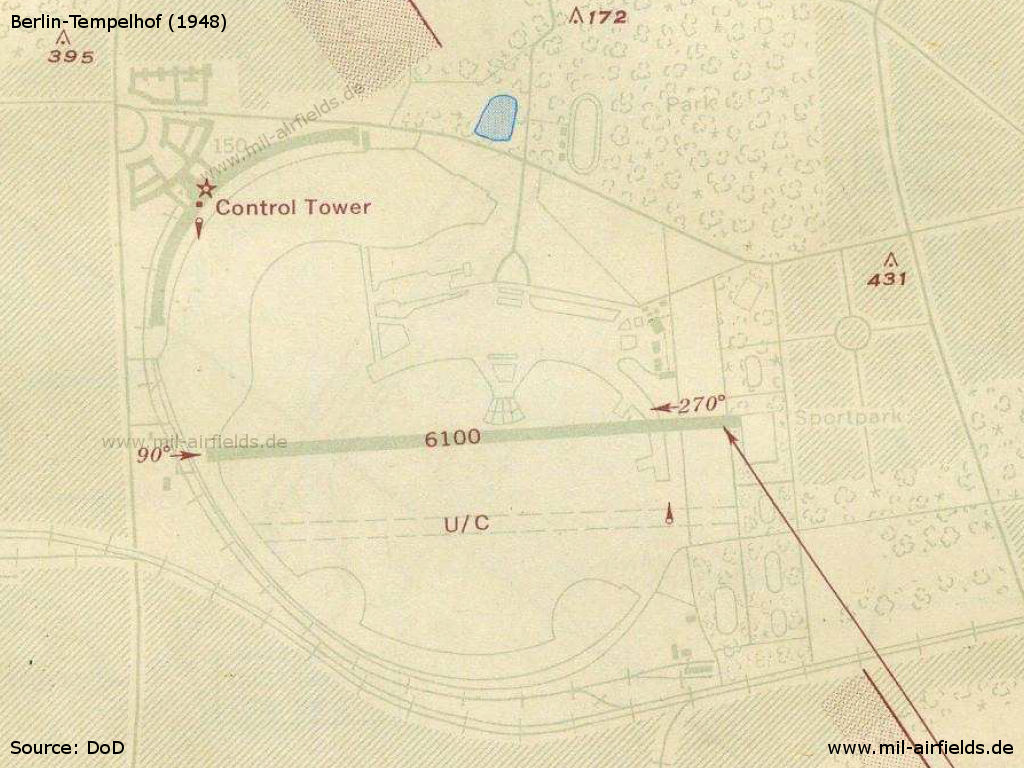

Map from September 1948, when the airlift was in progress. - In Tempelhof there was a paved runway, the later northern runway. The southern runway is under construction. The location of the tower at that time is marked.

Images

After 1945

Aerial picture winter 1947/1948 (Photo: Berliner Flughäfen / Archiv)

Approach from the east over the cemetery in 1948 (Photo: Berliner Flughäfen / Archiv)

Contents

Page 1: From the beginnings until 1945

Page 2: Tempelhof after World War II & Berlin Airlift ← you are here

Page 3: Tempelhof Airport: The 1950s